It was just like any other day. I came home to my family’s hovel, where all four of my grandparents sleep in the same bed, sailor style, because we live in such abject poverty. I had saved up my shillings to buy a pack of katsuobushi, Japanese dried bonito flakes that are the backbone of dashi (a soup stock that is the essential building block of Japanese cuisine) so I could cook a delicious meal. I opened up the pack to get to the fluffy fishy delights, and a golden ticket came fluttering out.

It was an invitation to a tour of the local katsuobushi factory, owned by the eccentric and reclusive Karl Katsuobushi. Upon this discovery, my grandpa lept out of bed, having suddenly regained his mobility. We were whisked off to the factory, which was run by impish humanoids who reeked of fish and communicated solely by singing in Japanese. Some of the other children on the tour didn’t follow Karl Katsuobushi’s instructions, and fell into the smoking pit, were sliced into paper-thin strips, or inadvertently sealed into a plastic bag and boxed up. At the end of the tour, Karl Katsuobushi revealed that this tour was actually a method of selecting the heir to the factory, and I had won through my innocence and good nature.

Okay I’m joking. There is no Karl Katsuobushi. But there is Marutomo, a company based in Iyo that produces katsuobushi. I’ve driven and walked by the factory on numerous occasions, and can even catch a whiff of katsuobushi in the air. I mused out loud that I wanted to do a tour, and my amazing supervisor managed to set it up for us. Was it like Wonka’s Chocolate Factory (the Gene Wilder one, all others are illegitimate) or was it more like the box factory tour from The Simpsons? Read on to find out…

Walking in, I had no clue what to expect. We were looking at a corporate office with a waiting area where you could peruse some of Marutomo’s excellent products. I don’t know what everything this, but there’s katsuobushi made from all types of fish, dashi, and a little chart illustrating how you can utilize katsuobushi all year round in seasonal dishes.

We were ushered into a corporate boardroom where we were treated to a slideshow that, being in Japanese mostly went over my head. There was information about the company’s products which also include dashi and other processed seafood stuffs. Statistics about amino acids and what products contain the most umami/naturally-occuring MSG (spoiler alert: katsuobushi is #1, and apparently grasshoppers aren’t too far behind). At this point I had flashbacks to when I took a Japanese food class in Singapore and my class was visited by the good people from Ajinomoto, the company that first isolated MSG more than a century ago. There we did some MSG taste testing with miso soup.

Zoom in on the middle image: as you may have gathered from the image on the top of the package, this is a special type of katsuobushi that your furry friends (pets) can enjoy

An overview of production rounded out the presentation. For the uninitiated, here’s a quick overview of the process:

- Pull a whole mess of skipjack tuna out of the ocean

- Simmer, then manually remove skin and bones

- Smoke the fish in sessions for at least a week, I think the Marumoto people said 10 days

- In between smoking sessions, cool and rest the fish so moisture evaporates

- When the fish resembles a piece of petrified wood, you’re ready for the next step –> in this state it is called arabushi, or low-grade katsuobushi

- Shave down with a grinder/sander tool until they are the right size and shape –> now you’re at hadakabushi

- Apply koji (a type of mold used to ferment rice to make sake or shochu, to ferment soybeans to make soy sauce or miso, and a whole lot more – scientific name: aspergillus oryzae) to fish, transfer to fermentation cellar (I gotta get me one of those, so I can put my katsuobushi next to my capicola, jamon iberico, kimchi, and kombucha)

- Ferment (process known as kabi tsuke) for about two months, scraping off the mold when it dries and re-applying koji, and congrats because your hadakabushi is now karebushi, or high-grade katsuobushi

- Run your katsuobushi through a metal detector, brush the fish to clean them, steam them, and then cool them

- Shave by hand into paper-thin, almost translucent flakes

- Shake them in a massive sieve conveyor belt to filter out the fine dust

- Weigh the flakes, package them, and use a special nozzle to shoot nitrogen gas into the bags before sealing them to preserve freshness

Sorry, that wasn’t very quick. But hey, it’s a complicated process to turn a fish into something you shave into fine strips with a razor blade, which I got to try for myself. The careful, deliberate process reminded me of the scene in the animated mockumentary Surf’s Up (2007) where the surfing master Big Z (Jeff Bridges) teaches the young buck Cody (Shia LeBeouf) how to carve his own board out of koa wood, which takes patience and precision. Though I was not attempting to sculpt a surfboard out of katsuobushi, I did try to carefully produce nice coily flakes without slicing any fingertips off. We also got to sample the katsuobushi at the different stages of production, as well as special types that are made with different types of fish.

You can see the petrified fish here, and how crazy it looks. It looks almost like a weapon, like an arrowhead or axe blade or something. Also me cheesing because I got to try the grating process.

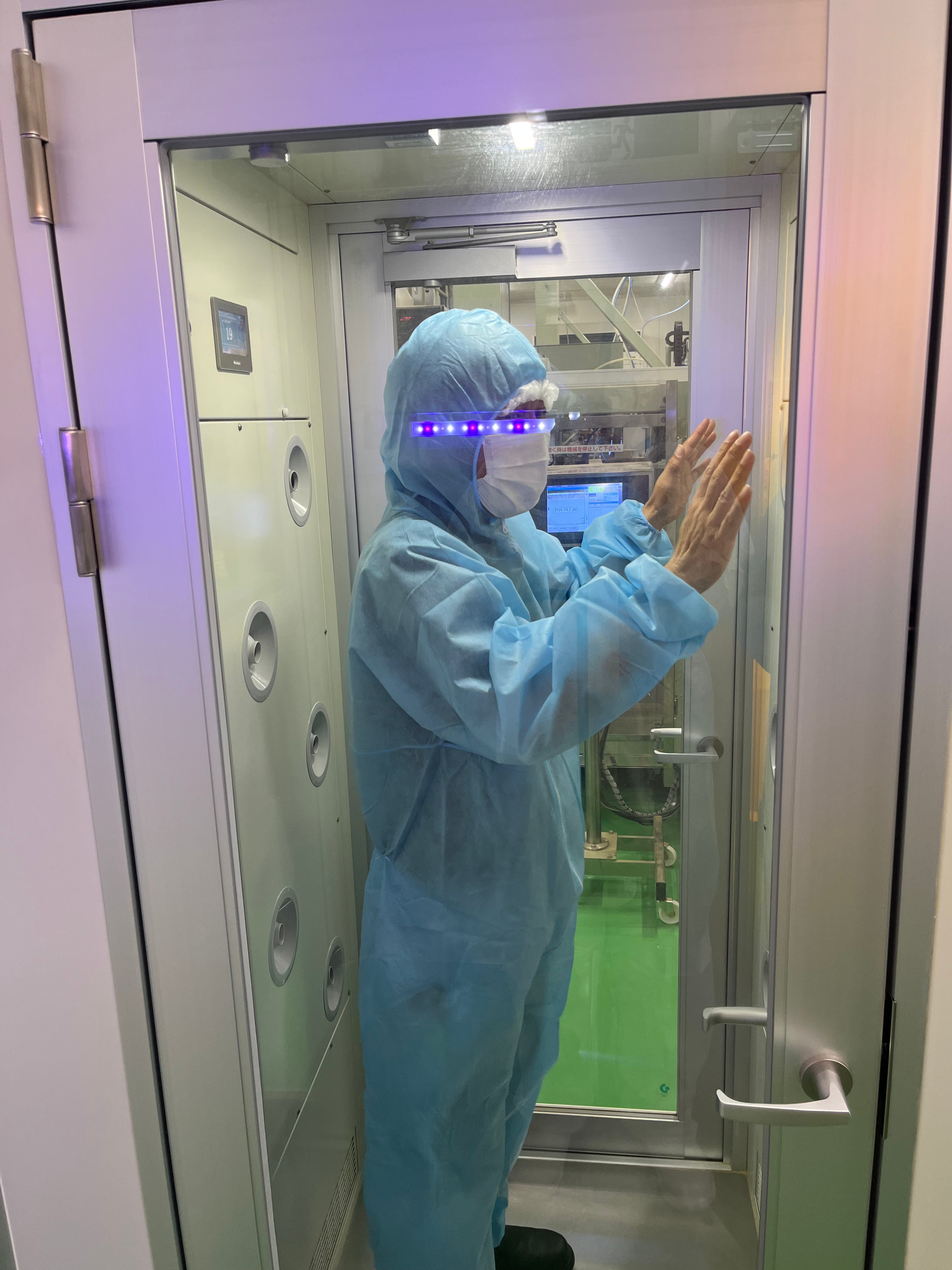

Now it’s time for the fun part, where I dress up like the Michelin Man and sanitize my hands five different times in preparation for visiting the factory floor. Our helpful tour guide has to run off into the closet to find a pair of shoes that are big enough for me.

First we see the fish during step 5, the koji application (I think). These molded fish blocks break off cleanly when you hit two pieces together like a drummer counting off time. The inside is smooth and glassy, as if this was a geode and not a fish. Those smaller fish on the right are iwashi, or sardines (for which the heads are not removed).

Fish in various stages are stacked up in crates, and on the right is saba, or mackerel.

Here is one of the master grinders in process, expertly holding a fish to a spinning succession of razor blades.

More of the assembly line. Henry Ford would have appreciated this if he hadn’t been a raging bigot.

And finally, it’s time to take the air shower! You enter the chamber and are fanned from all sides to clean yourself.

At the conclusion of our tour, we were bombarded with gifts in the form of all sorts of cooking ingredients, most of which I don’t even know what they are. One of them was definitely furekake, but beyond that I’m not too sure. I’ll have to investigate. Who knows, maybe I can get a tour of the soy sauce factory next.

Leave a reply to mete Cancel reply